Recognizing Membrane Switches: The Secret to Trustworthy and resilient Controls

Membrane layer switches stand for an essential aspect of modern-day user interface style, blending capability with strength in various applications. As we discover the details of membrane switches, it becomes clear that their duty in boosting control systems is both extensive and intricate, elevating questions concerning exactly how finest to take advantage of their capacities in future technologies.

What Are Membrane Layer Switches?

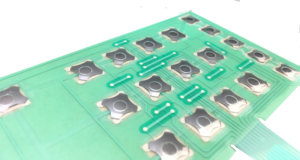

Membrane layer switches are an innovative remedy in the world of interface modern technology, combining performance and design flawlessly. These devices work as an interface between customers and electronic systems, integrating a number of components right into a compact format. Commonly built from flexible, slim layers of materials, membrane layer switches are designed to reply to touch, allowing customers to connect with machinery and digital devices properly.

The main elements of a membrane switch consist of a published circuit layer, visuals overlay, and a spacer layer that prevents unintended activation. The graphic overlay can be customized to reflect brand name identification or individual choices, improving aesthetics while making sure use. Membrane buttons are generally utilized in different applications, including medical tools, customer electronics, and industrial tools, owing to their durability and resistance to ecological aspects such as moisture and dirt.

Among the crucial benefits of membrane layer buttons is their capability to withstand deterioration, making them ideal for high-traffic atmospheres. Furthermore, they are lightweight and require marginal area, permitting cutting-edge layouts in product growth. Overall, membrane switches over stand for a sensible and effective option for modern digital interfaces, weding innovation with user-centric layout principles.

How Membrane Switches Over Job

The operation of membrane layer switches over joints on a simple yet effective mechanism that converts customer input right into digital signals. When a user presses the button, the leading layer warps, permitting a conductive component in the circuit layer to make call with a corresponding conductive pad on the bottom of the graphic overlay.

The layout of membrane switches can differ, however they frequently include domes or tactile components to offer comments to the user, enhancing the general experience. The products utilized in membrane buttons, such as polyester or polycarbonate, add to their sturdiness and resistance to ecological elements, including dampness and dust. The published circuits are usually encapsulated, which protects them from wear and tear over time.

Advantages of Membrane Buttons

Among the key advantages of membrane switches is their versatility in style, permitting them to be tailored to satisfy particular individual needs and visual needs. This adaptability encompasses numerous markets, where different forms, dimensions, and shades can be utilized to boost individual communication and aesthetic allure.

Additionally, membrane layer switches are known for their longevity. Created from durable materials, they are resistant to dust, wetness, and physical wear, which dramatically prolongs their lifespan contrasted to conventional mechanical buttons. This resilience makes them particularly appropriate for high-traffic environments and a fantastic read applications requiring long life.

Moreover, membrane layer switches provide a structured profile, bring about a thinner layout that can be incorporated into numerous tools without adding bulk. This attribute not only improves the aesthetic charm however likewise adds to an extra ergonomic product design.

Applications of Membrane Layer Buttons

Functional and easy to use, membrane buttons find applications throughout a vast array of sectors, including clinical devices, consumer electronic devices, and industrial equipment. In the medical area, these buttons are essential to devices such as diagnostic devices, person tracking systems, and mixture pumps, where dependability and convenience of cleaning are crucial. Their capability to withstand rough environments and preserve capability makes them excellent for such applications.

In consumer electronic devices, membrane buttons are made use of in products like microwaves, washing devices, and remotes - membrane switch. Their sleek layout permits intuitive interface, boosting the total customer experience while offering longevity and resistance to use and tear

Commercial equipment also benefits from membrane switches, specifically in control panels for machinery and automation systems. These switches provide defense versus dirt and moisture, making certain consistent performance in tough atmospheres. Moreover, their adjustable attributes permit suppliers to tailor them to specific functional requirements, enhancing performance and capability.

Selecting the Right Membrane Layer Change

When picking a membrane button, it is important to read this post here take into consideration various elements that affect performance and viability for certain applications. The main factors to consider consist of ecological problems, responsive responses, longevity, and design requirements.

First, evaluate the operating environment; buttons subjected to moisture, chemicals, or severe temperatures require specific materials to make sure durability and functionality. Next, assess the requirement for tactile responses. Relying on individual communication, some applications may take advantage of a responsive response to confirm activation, while others might prefer a read the full info here non-tactile style for visual factors.

Longevity is another important element; membrane layer buttons should be made to stand up to constant use, impacts, and abrasion. Make sure the chosen switch can sustain the expected lifecycle, especially in high-usage scenarios.

Final Thought

To conclude, membrane layer switches over act as crucial components in the design of reliable and resilient control systems throughout various sectors. Their small style, incorporated with robust building and construction and personalized functions, boosts user interaction while making sure durability sought after environments. The flexibility of membrane layer switches enables for customized services that meet certain operational requirements, reinforcing their importance in modern innovation. membrane switch. As markets remain to develop, the importance of incorporating efficient membrane layer button services can not be overemphasized.

Membrane layer switches represent a critical element of modern-day interface layout, mixing performance with resilience in various applications.Membrane buttons are an advanced service in the world of user interface modern technology, integrating capability and design effortlessly. Generally built from versatile, slim layers of products, membrane switches are created to respond to touch, allowing customers to communicate with machinery and electronic devices effectively.

The design of membrane switches can vary, but they commonly incorporate domes or tactile elements to give feedback to the user, improving the overall experience.In verdict, membrane layer changes serve as vital components in the design of sturdy and reliable control systems across various industries.

Comments on “Why Membrane Switches Are the Preferred Choice for Compact Devices”